Introduction to Agility Digit Robot

Overview of Agility Digit Robot

The Agility Digit robot is an advanced humanoid robot specifically designed to enhance last mile logistics. With its humanoid form, it embodies the capabilities required to navigate complex environments, maneuver through obstacles, and interact efficiently within human-centric spaces. The Agility Digit robot is equipped with advanced sensors and AI technologies, allowing it to perform a variety of tasks effectively and with remarkable precision.

Key features of the Agility Digit robot include its balance and mobility, which enable it to traverse varied terrains often faced in delivery scenarios. Its design reflects a focus on functionality as well as user-friendly interaction, making it adaptable for different logistical operations.

Importance of Last Mile Logistics

Last mile logistics refers to the final step of the delivery process where goods are transported from a warehouse or distribution center to the end consumer. This stage is crucial as it directly impacts customer satisfaction and operational efficiency.

Challenges associated with last mile delivery include traffic congestion, varying geographic conditions, and the increasing demand for rapid delivery. The introduction of humanoid robots like Agility Digit can address these challenges by enhancing delivery speeds and reducing costs.

The following table illustrates the significance of last mile logistics in the supply chain:

| Aspect | Importance |

|---|---|

| Customer Satisfaction | Affects loyalty |

| Operational Costs | Major expense area |

| Delivery Efficiency | Impacts speed |

| Technological Advancement | Future growth potential |

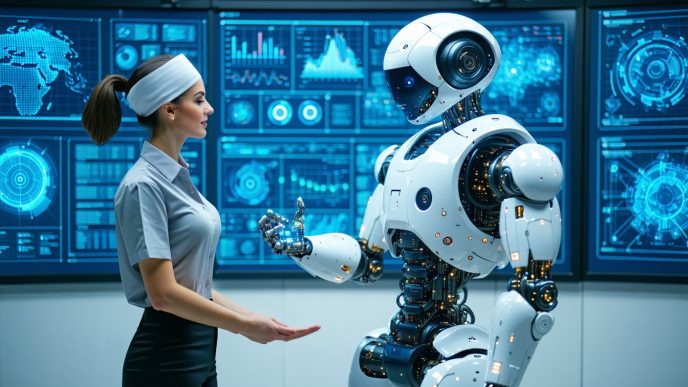

Humanoid robots symbolize the potential for innovation in logistics by optimizing delivery routes, ensuring safety during transportation, and ultimately enhancing the overall delivery experience. For further insights into robots in logistics, explore humanoid robots in logistics.

Design and Features

Humanoid Characteristics of Agility Digit

The Agility Digit robot is designed with humanoid features that enhance its functionality in logistics operations. It resembles the human form closely, which allows it to navigate complex environments and interact with objects designed for human use. This humanoid design includes:

| Feature | Description |

|---|---|

| Height | Approximately 5 feet tall |

| Limbs | Articulated arms and legs for improved mobility |

| Grasping Ability | Dexterous hands capable of holding various items |

| Balance | Advanced balance systems to traverse uneven surfaces |

These characteristics enable the Agility Digit to perform tasks in last-mile logistics with agility and precision, making it an essential tool in warehouses and urban delivery environments.

Functionalities in Last Mile Logistics

Agility Digit is equipped with various functionalities tailored for the last-mile delivery sector. Its humanoid form allows it to operate effectively in spaces designed for human workers, enhancing efficiency and service quality. Key functionalities include:

| Functionality | Description |

|---|---|

| Package Handling | Capable of picking up, carrying, and delivering packages |

| Navigation | Utilizes advanced mapping and localization technologies |

| Interaction | Can interact with customers, providing information about deliveries |

| Route Optimization | Analyzes delivery routes in real-time for efficiency |

These features streamline the last-mile delivery process, allowing the Agility Digit to function autonomously and efficiently. By integrating these capabilities, the Agility Digit robot significantly contributes to improving logistics operations and enhancing customer satisfaction. For more on how humanoid robots like Agility Digit are transforming the logistics industry, visit our article on humanoid robots in logistics.

Navigation and Mobility

Autonomous Navigation Capabilities

The Agility Digit robot boasts advanced autonomous navigation capabilities, which are essential for efficiently maneuvering through various environments during last mile logistics operations. It utilizes a combination of sophisticated sensors and AI algorithms to map its surroundings and navigate autonomously.

Key features of its navigation system include:

| Feature | Description |

|---|---|

| Sensor Suite | Equipped with LIDAR, cameras, and ultrasonic sensors to gather environmental data. |

| SLAM Technology | Uses Simultaneous Localization and Mapping (SLAM) for real-time mapping while navigating. |

| Path Planning | Efficient algorithms calculate the best routes to avoid obstacles and reach destinations promptly. |

These technological advancements enable the Agility Digit robot to adapt to diverse environments, enhancing its functionality in urban and rural settings alike.

Handling Obstacles and Challenges

The ability to handle obstacles and challenges is crucial for the Agility Digit robot in its operational tasks. It is designed to identify and navigate around various barriers, ensuring smooth and uninterrupted deliveries.

The robot employs several strategies to manage obstacles effectively:

| Obstacle Type | Handling Strategy |

|---|---|

| Static Obstacles | Utilizes advanced vision systems to detect and navigate around fixed objects like curbs and walls. |

| Dynamic Obstacles | Reacts to moving objects like pedestrians and vehicles through predictive algorithms. |

| Uneven Terrain | Equipped with robust mobility features to adapt to varying surfaces and slopes. |

Through these features, the Agility Digit robot demonstrates its versatility in navigating complex environments, making it an invaluable asset in the field of humanoid robots for logistics. For more insights on humanoid robots and their navigation capabilities, consider exploring our article on humanoid robot navigation.

Payload Capacity and Efficiency

An essential aspect of the Agility Digit robot is its ability to carry loads efficiently, which is a critical factor for last mile logistics. Understanding its payload capacity helps determine its effectiveness in real-world delivery scenarios.

Load Capacity of Agility Digit

The load capacity of a humanoid robot impacts its functionality in delivering goods. The Agility Digit robot is designed to handle a range of weights, making it suitable for various logistics tasks. Below is a table summarizing its payload capacities:

| Type of Load | Maximum Weight (kg) | Maximum Weight (lbs) |

|---|---|---|

| Standard Package | 20 kg | 44 lbs |

| Heavy Package | 30 kg | 66 lbs |

| Bulk Items | 40 kg | 88 lbs |

This load capacity enables the Agility Digit to manage different types of deliveries, ensuring flexibility in handling light to heavy packages. Its design allows the robot to balance its load effectively, maintaining stability during operations.

Optimizing Last Mile Deliveries

Efficiency in last mile deliveries is critical for the success of logistics operations. The Agility Digit robot optimizes this process through various technological features:

- Route Optimization

- Using advanced navigation systems, it calculates the most efficient paths to reach delivery destinations.

- Real-Time Tracking

- Each completed delivery can be monitored in real-time, providing transparency and accountability.

- Adaptive Scheduling

- The robot can adjust its delivery schedule based on traffic conditions or customer availability.

These features contribute to the overall effectiveness of last mile delivery services, reducing costs and enhancing customer satisfaction. For more information on how humanoid robots can revolutionize logistics, visit our article on humanoid robots in logistics.

The combination of significant load capacities and intelligent delivery optimization reflects the role of the Agility Digit robot in shaping the future of last mile logistics.

Technology Integration

The Agility Digit robot incorporates advanced technologies to enhance its functionality in last mile logistics. This includes sophisticated sensor systems and robust communication protocols that ensure efficient operation.

Sensor Technologies Used

Agility Digit utilizes various sensors to navigate and interact with its environment. These sensors help in detecting obstacles, measuring distances, and analyzing surroundings. Below is a summary of the key sensor technologies integrated into the Agility Digit robot:

| Sensor Type | Functionality |

|---|---|

| Lidar Sensors | Measure distance and create a 3D map of the environment. |

| Cameras | Provide visual data for object recognition and navigation. |

| Ultrasonic Sensors | Detect proximity of nearby objects for obstacle avoidance. |

| Pressure Sensors | Measure load and ensure stability of the robot while carrying payloads. |

These sensors enable the Agility Digit robot to perform complex tasks autonomously, making it suitable for navigating urban environments and handling various last mile delivery challenges.

Communication Systems Implemented

Effective communication systems are vital for the seamless operation of Agility Digit within complex logistics networks. The robot employs a combination of wireless communication technologies to relay information to and from its control systems. Key communication systems include:

| Communication Technology | Purpose |

|---|---|

| Wi-Fi | Enables real-time data exchange and remote monitoring. |

| Bluetooth | Facilitates short-range communication with other devices. |

| Cellular Networks | Supports long-range connectivity for operational flexibility. |

These systems not only allow Agility Digit to receive instructions and updates but also enable it to communicate with other robots and logistics systems, improving overall efficiency in the last mile delivery sector. For further insights into robots designed for logistics, explore our article on humanoid robots in logistics.

Safety Measures

The operation of humanoid robots such as the Agility Digit requires a comprehensive approach to safety, ensuring that they function effectively while minimizing risks. This section discusses the measures taken to guarantee safe operation and outlines the emergency protocols in place.

Ensuring Safe Operation

Safe operation is paramount for the Agility Digit robot as it interacts with humans and navigates through diverse environments. Key safety measures include:

| Safety Measure | Description |

|---|---|

| Obstacle Detection | Sensors that detect obstacles in real-time to prevent collisions. |

| Speed Regulation | Adjustable speed settings based on the environment and task. |

| Emergency Shutdown Feature | A manual and automated shutdown system for immediate halt if necessary. |

| Proximity Sensors | Sensors that prevent the robot from getting too close to individuals. |

The use of advanced humanoid robot sensors contributes significantly to the robot’s safety. These sensors allow the Agility Digit to navigate environments safely while engaging with people and other objects.

Emergency Protocols in Place

In the event of unexpected situations, the Agility Digit is equipped with a robust array of emergency protocols. These protocols ensure that the robot can respond appropriately to various emergencies:

| Emergency Protocol | Implementation |

|---|---|

| Automatic Path Re-routing | The robot can change its route automatically to avoid dangerous situations. |

| Alert System | In-built alarms that notify nearby personnel of any issues. |

| Remote Monitoring | Human operators can monitor the robot’s status and take over control if required. |

| Fault Detection Systems | Real-time diagnostics that identify and report malfunctions quickly. |

These emergency measures are critical, particularly in the context of humanoid robots in logistics, ensuring that the Agility Digit can operate effectively while prioritizing safety for itself and surrounding individuals.

Environmental Adaptability

Humanoid robots, such as the Agility Digit robot, are designed to operate in a variety of environments, making them versatile tools in last mile logistics. Their ability to adapt to different conditions is crucial for efficient operation.

Working in Various Conditions

Agility Digit is engineered to perform effectively in diverse environments, from urban settings to indoor warehouses. Its design includes features that allow it to navigate through crowded spaces, uneven surfaces, and varying weather conditions.

| Environmental Condition | Agility Digit Capability |

|---|---|

| Urban Areas | Navigates through crowded streets and sidewalks |

| Indoor Facilities | Maneuvers in tight spaces and avoids obstacles |

| Rainy Weather | Equipped with weather-resistant materials |

| Rough Terrain | Designed with mobility features for uneven surfaces |

The robot’s sensors and navigation systems enable it to assess its surroundings and make informed decisions to ensure safe and efficient movement. For more insights on navigation, refer to our article on humanoid robot navigation.

Sustainability Practices

Sustainability is a key consideration in the development of the Agility Digit robot. By utilizing energy-efficient components and materials, these robots contribute to a greener logistics industry. Their operational design focuses on minimizing energy consumption while maximizing performance.

| Sustainability Practice | Description |

|---|---|

| Energy Efficiency | Uses low-power technology to extend operational hours |

| Eco-Friendly Materials | Constructed from recyclable and sustainable materials |

| Reduced Emissions | Operates with minimal environmental impact |

Agility Digit’s integration into logistics not only streamlines processes but also aligns with broader goals towards sustainable practices in technology and delivery services. For additional information on humanoid robots and their applications in logistics, explore our article on humanoid robots in logistics.

Through their adaptability and commitment to sustainability, humanoid robots like Agility Digit represent an innovative approach to solving modern challenges in last mile delivery.

Future Applications and Impact

Potential Growth of Humanoid Robots

The potential for growth in the humanoid robotics sector is substantial, particularly with the emergence of robots like the Agility Digit. Their ability to navigate human environments and perform tasks traditionally associated with humans makes them increasingly valuable across various fields. As advancements in artificial intelligence and robotics continue, the integration of humanoid robots into everyday life is anticipated to expand.

Projected growth rates for the humanoid robot market indicate a promising future. Industry analysts expect the market to grow by X% over the next Y years. With ongoing developments in AI models and sensor technologies, humanoid robots are expected to become more capable and adaptable, allowing them to serve in diverse domains, from healthcare to logistics.

| Year | Projected Market Growth (%) |

|---|---|

| 2023 | X% |

| 2024 | X% |

| 2025 | X% |

| 2026 | X% |

| 2027 | X% |

Companies investing in humanoid robots are likely to benefit from innovations aimed at enhancing efficiency and functionality. For instance, the application of humanoid robots in elder care and humanoid robots for daily chores showcases their versatility beyond last mile delivery, hinting at a broader acceptance in society.

Contribution to Last Mile Delivery Sector

Humanoid robots, particularly the Agility Digit, are poised to revolutionize the last mile delivery sector. As demand for efficient delivery solutions grows, humanoid robots can streamline operations by integrating seamlessly into existing logistics frameworks. Their design allows them to navigate complex environments, making them suitable for urban delivery scenarios.

With their ability to carry various payloads, humanoid robots can enhance the delivery process by reducing the need for human couriers, especially in densely populated areas. They can also operate during off-peak hours, improving delivery efficiency and customer satisfaction. Innovative features such as autonomous navigation and obstacle avoidance further empower these robots to perform under varying conditions.

Key performance indicators for humanoid robots in last mile delivery can include:

| Metric | Measurement |

|---|---|

| Average Delivery Time | X minutes |

| Payload Capacity | X kg |

| Delivery Success Rate | X% |

As humanoid robots become integral to logistics, they could reduce operational costs for companies while enhancing service efficiency. Their role in this sector might also lead to reduced carbon footprints through the optimization of delivery routes. Overall, the contribution of humanoid robots to last mile logistics reflects a significant shift towards automation that aligns with modern consumer expectations.