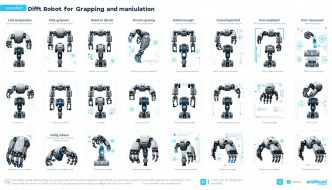

Robot Precision in Object Handling

Overview of Robot Precision

Robot precision in object handling refers to the accuracy with which robotic systems can grasp, manipulate, and release various objects. This characteristic is essential in determining a robot’s effectiveness in tasks that require finesse, such as assembling parts, handling fragile items, or performing delicate procedures. Precision encompasses various factors, including grip strength, positioning accuracy, and the robot’s ability to adapt to different shapes and materials.

The best robots for grasping and manipulation must integrate advanced technologies and algorithms that enhance their operational precision. This includes sophisticated sensors that provide feedback on grip and position, as well as algorithms that enable real-time adjustments to grip techniques based on the object being handled.

| Precision Factor | Description |

|---|---|

| Grip Strength | Force applied when grasping an object |

| Position Accuracy | Precision in locating and placing objects |

| Adaptive Techniques | Ability to adjust grip styles for different objects |

Importance of Precision in Object Handling

Precision in object handling is crucial for several reasons. First, it reduces the likelihood of mistakes, such as dropping or damaging items, which can lead to costly errors in industrial settings. Second, high precision can enhance productivity by increasing the robot’s efficiency in completing tasks without requiring extensive rework. Further, precision is vital for application areas requiring delicacy, such as healthcare and research, where the interaction with sensitive instruments or specimens demands the highest level of care.

Precision impacts user satisfaction, particularly in personal assistant robots designed for home use. Effective handling of household items enhances the usability and functionality of these robots, making them more appealing to consumers. The growing reliance on robots in various sectors such as manufacturing, healthcare, and home care emphasizes the importance of precision, which can be compared through feature specific robot comparisons for informed decision-making.

| Application Area | Impact of Precision |

|---|---|

| Manufacturing | Increases productivity and decreases waste |

| Healthcare | Enhances safety during delicate procedures |

| Household Management | Improves user experience and satisfaction |

Understanding the significance of precision in object handling not only helps in selecting the most suitable robots for specific tasks but also guides advancements in robotics technology for better human-robot interaction.

Grasping Ability Comparison

Evaluating the grasping ability of robots is essential for determining which one excels in manipulation tasks. Various factors influence this capability, and several techniques offer methods for enhancing precision.

Factors Affecting Grasping Ability

Several key factors can impact a robot’s grasping efficiency. Understanding these elements is crucial for comparing robots effectively.

| Factor | Description |

|---|---|

| Robot Design | The physical configuration, including arm length and joint flexibility, plays a significant role in grasping. |

| Grip Mechanism | Different types of grippers, such as parallel, suction, or adaptive grippers, affect the range of objects a robot can handle. |

| Sensory Feedback | The use of sensors for object detection and force feedback helps in adjusting the grip strength and position accurately. |

| Software Algorithms | The algorithms guiding the robot’s grabbing actions are vital for adapting to various objects and environments. |

| Material Composition | The materials used for the gripper’s surface can influence how well it holds onto different objects. |

Techniques for Precise Grasping

Robots employ various techniques to enhance their grasping precision. These methods are essential for accomplishing intricate manipulation tasks successfully.

| Technique | Description |

|---|---|

| Force Control | Adjusting the gripping force based on the object’s size and fragility to prevent damage while ensuring a secure hold. |

| Vision Systems | Utilizing cameras and image processing to identify and locate objects accurately before grasping. |

| Machine Learning | Employing machine learning algorithms to improve the robot’s grasping skills through learning from past experiences. |

| Adaptive Gripping | Implementing grippers that can change shape or adjust their grip based on the object’s geometry, enhancing versatility. |

| Simulation Testing | Conducting simulations to evaluate and refine grasping strategies before actual manipulation tasks are performed. |

Comparing different robots based on these factors and techniques can help individuals identify the best robot for grasping and manipulation according to specific needs. For further insights into robotic comparisons, explore our feature specific robot comparisons.

AI Intelligence Evaluation

The integration of artificial intelligence is changing the landscape of robotic capabilities, especially when it comes to precision in object handling. AI enhances a robot’s ability to perceive, learn, and adapt, resulting in improved proficiency in grasping and manipulation tasks.

Role of AI in Enhancing Precision

AI algorithms significantly contribute to a robot’s accuracy by processing data from various sensors. This data helps the robot to understand the environment, recognize objects, and predict how to interact with them effectively. Machine learning techniques enable robots to learn from experience, refining their precision over time.

Key areas where AI boosts precision include:

- Object Recognition: Using computer vision, AI helps robots identify and classify objects effectively. This capability is crucial for selecting the right handling approach.

- Adaptive Grasping: AI enables robots to adjust their gripping force and position based on the object’s characteristics, reducing the likelihood of dropping or damaging items.

| AI Feature | Description |

|---|---|

| Object Recognition | Ability to identify and classify various objects |

| Adaptive Grasping | Adjustment of grip strength based on object type |

| Learning from Experience | Improvement in precision through machine learning |

Applications of AI in Object Handling

Artificial intelligence finds a variety of applications in the realm of object handling. These applications span across different industries and tasks, showcasing the versatility of AI-enhanced robots.

Some notable applications include:

- Manufacturing: AI-driven robots perform assembly tasks, sorting, and packaging with high precision, leading to efficient production lines.

- Healthcare: Robots equipped with AI can assist in surgical procedures, handling instruments or materials with utmost care.

- Logistics: In warehouses, AI robots manage inventory and shipping, handling packages of various sizes and weights effectively.

- Home Assistance: Robots help in household chores by picking up and organizing items, especially in environments shared with children or pets.

| Application Area | Key Tasks |

|---|---|

| Manufacturing | Assembly, sorting, packaging |

| Healthcare | Surgical assistance, handling instruments |

| Logistics | Inventory management, shipping |

| Home Assistance | Household chores, organization |

By employing advanced AI techniques, robots are increasingly becoming the best option for grasping and manipulation tasks. For those interested in comparing features specific to robots, the article on feature specific robot comparisons provides detailed insights into various robot functionalities.

Navigation Skill Assessment

Importance of Navigation Skill

Navigation skills play a crucial role in a robot’s ability to maneuver in various environments effectively. A robot with advanced navigation capabilities can efficiently handle tasks that require precision in movement, such as grasping and manipulation. This ability is essential in applications like warehouse management, where robots must navigate around obstacles and reach specific locations without error.

Robots equipped with superior navigation skills are better at avoiding collisions and managing dynamic obstacles, enhancing their utility in complex environments. Accurate navigation not only improves the efficiency of operations but also instills reliability and safety in tasks performed by robots. Understanding the nuances of navigation helps potential buyers distinguish between options when looking for the best robot for grasping and manipulation.

Methods for Enhancing Navigation Precision

Numerous techniques can be employed to improve a robot’s navigation precision. Here, we outline several key methods:

| Method | Description |

|---|---|

| Sensor Integration | Utilizing a variety of sensors (LiDAR, cameras, ultrasonic) enhances environmental awareness and obstacle detection. |

| SLAM (Simultaneous Localization and Mapping) | This technique allows robots to build a map of an unknown environment while keeping track of their current location. |

| Path Planning Algorithms | Efficient algorithms, such as A* and Dijkstra’s, help robots determine the most efficient routes to their destinations. |

| Machine Learning Techniques | Training robots on various terrain and obstacle scenarios improves their adaptability and navigation skills. |

| Real-Time Data Processing | Processing data in real time allows robots to react quickly to changes in their environment, improving navigational accuracy. |

By implementing these methods, manufacturers can create robots with enhanced navigation skills, contributing to their overall performance in tasks involving object handling and manipulation. For more insights on different types of navigational abilities, consider exploring articles about the best robot for navigation and mapping and the best robot for obstacle avoidance.

Battery Life Considerations

Battery life is a critical factor in determining a robot’s effectiveness in object handling and manipulation. As robots operate independently, their ability to function for extended periods directly impacts their performance in various tasks.

Impact of Battery Life on Object Handling

The battery life of a robot influences its operational efficiency and capability to handle objects precisely. Short battery life may result in interruptions during tasks, which can affect the robot’s ability to grasp and manipulate objects effectively.

| Battery Life Range | Operational Impact |

|---|---|

| Less than 1 hour | Limited task completion; frequent recharging required |

| 1-3 hours | Moderate performance; may complete simple tasks but risks interruptions |

| 4-8 hours | Reliable for most tasks; suitable for continuous operation |

| More than 8 hours | Highly efficient; ideal for demanding environments and prolonged tasks |

Robots with longer battery life can manage more complex operations, maintain precision in manipulation, and enhance productivity in environments where continual operation is necessary. The integration of energy-efficient technologies can further extend a robot’s effective working time.

Strategies for Prolonging Battery Life

Several strategies can be employed to maximize the battery life of robots, ensuring better performance during object handling:

-

Energy Efficient Components: Utilizing low-powered motors and processors can help reduce energy consumption during operation.

-

Optimized Algorithms: Implementing efficient algorithms for task execution and navigation can minimize unnecessary energy expenditure.

-

Regular Maintenance: Keeping the robot clean and well-maintained can enhance battery performance and longevity.

-

Battery Management Systems: Using sophisticated battery management systems allows for better monitoring and maintenance of battery health, optimizing charging cycles to prolong life.

-

Wireless Charging Solutions: Investigating wireless charging options can provide convenient ways to recharge robots during downtime without manual intervention.

-

Proper Schedulers: Scheduling tasks efficiently can allow robots to operate in bursts, conserving energy during idle times.

By focusing on these strategies, users can ensure that the best robot for grasping and manipulation achieves optimal battery efficiency, thus enhancing overall performance. For additional information regarding specific robot features, refer to our section on feature specific robot comparisons.

Future Trends in Robot Precision

As the field of robotics continues to evolve, advancements in object handling technology aim to improve the precision and efficiency of robots. These improvements are critical in various applications, ranging from industrial settings to personal assistance.

Advancements in Object Handling Technology

Recent developments in material science and engineering are leading to more sophisticated grippers and manipulators. These enhancements allow robots to grasp a wider variety of objects with greater accuracy. Key advancements include:

| Technology | Description |

|---|---|

| Soft Robotics | Uses flexible materials to create grippers that conform to objects, increasing the range of items that can be handled efficiently. |

| Adaptive Gripping | Incorporates sensors and AI to adjust grip strength and technique based on the object being handled. |

| Multi-Fingered Robots | Mimic human hand dexterity, allowing for complex manipulation tasks that require precision. |

Additional technologies such as haptic feedback systems enhance the robot’s ability to gauge the weight and texture of objects, further refining grasping capabilities. Innovations in control algorithms also allow for smoother and more precise movements by minimizing the risk of dropping or damaging items.

Potential Innovations for Enhanced Precision

Looking into the future, several innovations show promise for significantly improving robot precision in object handling. These innovations include:

| Innovation | Potential Impact |

|---|---|

| AI-Enhanced Vision | Utilizing advanced machine learning to improve object recognition, enabling robots to identify and manipulate objects more accurately in various environments. |

| Integrated Sensors | Incorporating temperature, pressure, and proximity sensors into robotic arms to enhance feedback during manipulation tasks. |

| Collaboration with Humans | Implementing collaborative robots (cobots) that work alongside humans, allowing for adaptive interaction and increased precision through shared tasks. |

As these technologies develop, the best robot for grasping and manipulation is likely to become more efficient and versatile. Enhanced precision will benefit sectors like manufacturing, healthcare, and service industries, where the accuracy of tasks is paramount.

For those interested in deeper comparisons of various robotic features, exploring feature specific robot comparisons can provide valuable insights. As innovations continue, the landscape of robotics will not only change how tasks are completed but also how robots interact with the world around them.